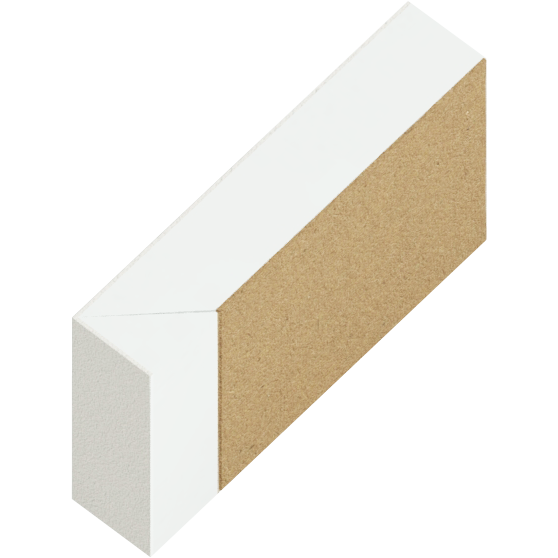

EXACT EDGE PREFORMED DRYWALL SHAPES

MADE-TO-ORDER CUSTOM DRYWALL SHAPES

Computer Modeled & CNC Machined Gypsum Board Shapes

EVER INCREASING PRODUCT CATALOG

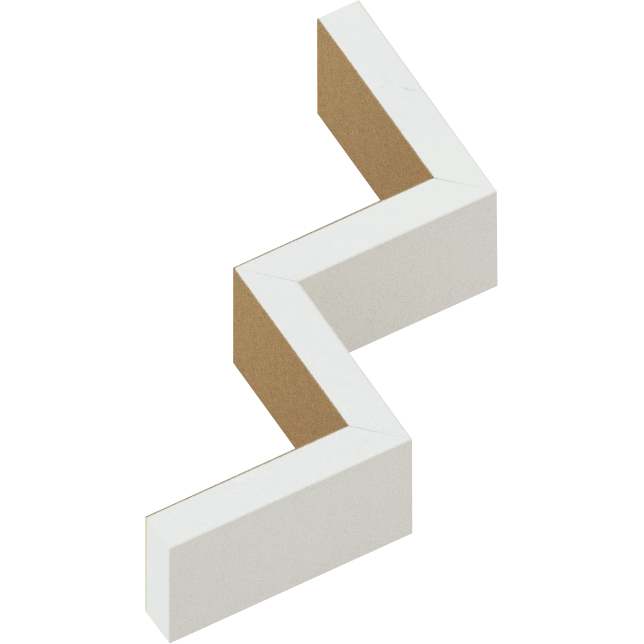

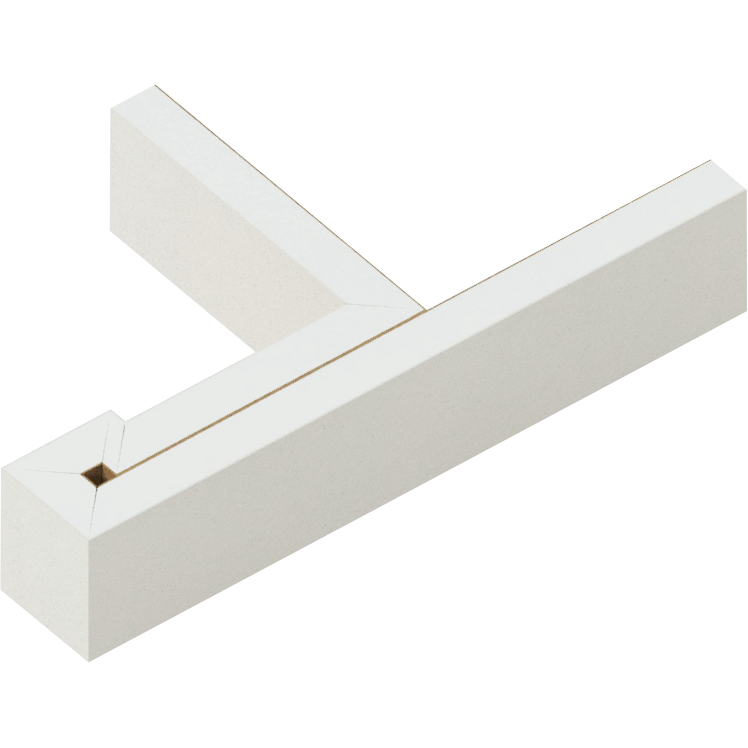

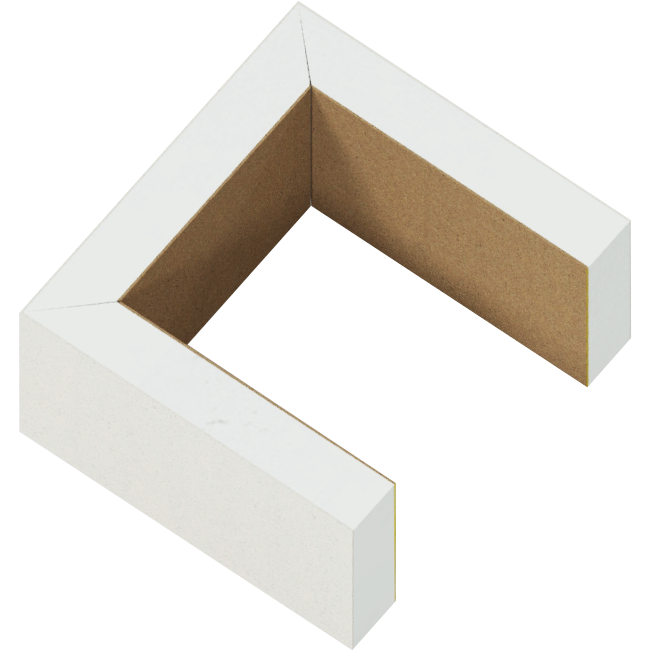

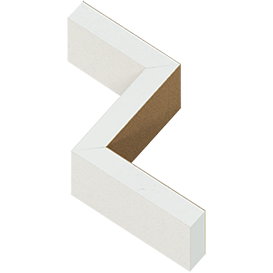

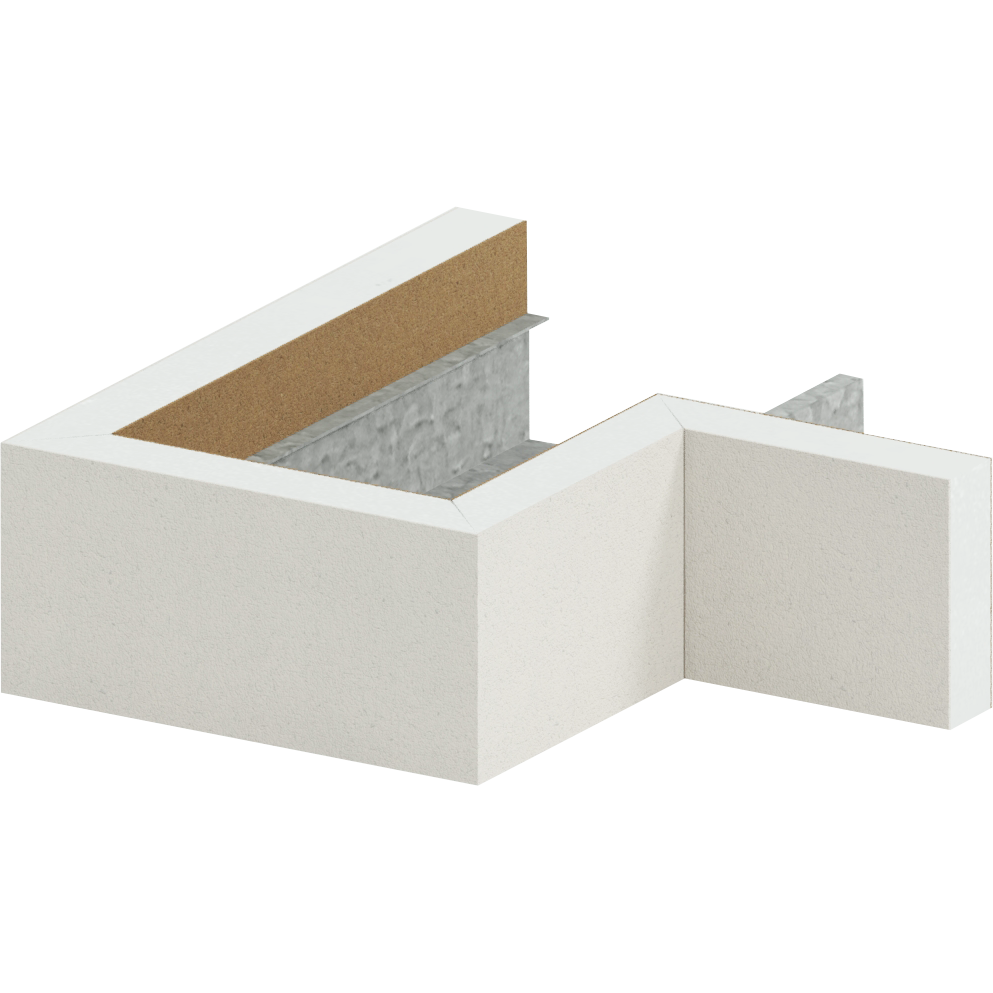

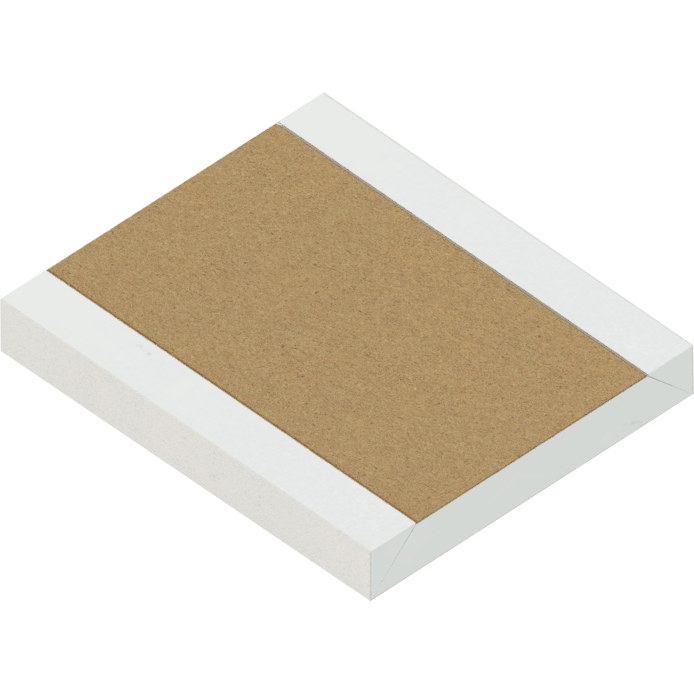

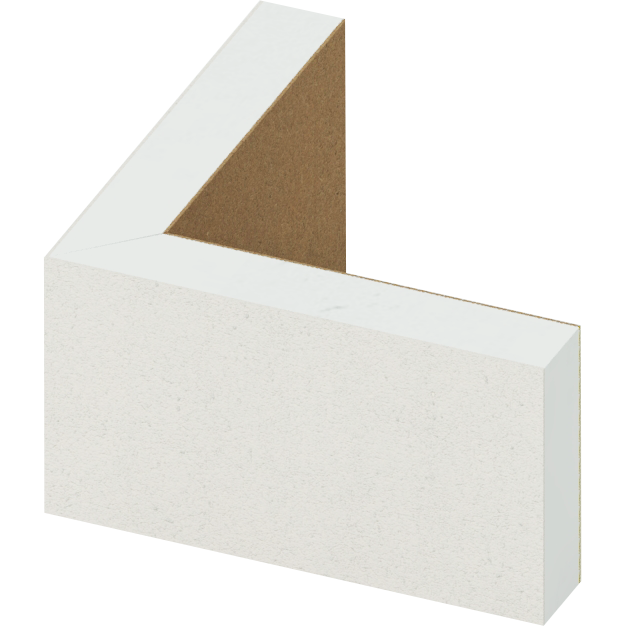

Our product catalog currently includes L-shapes, U-shapes, castle cuts, multi-step drops with returns, light coves, and window returns.

RELIABILITY

Each modeled Exact Edge piece is CNC machined to exacting specifications.

FEATURES & BENEFITS

ORDERING

- Easy-to-complete order form using building model, plans or field dimensions. Get a quote.

FINISHED PRODUCT

- Improved quality

- Exact, straight edges

ONSITE

- Near zero board waste

- Significantly less joint compound required

- Elimination of Corner Bead

- Reduced dust due to reduced sanding required

- Significant reduction in labor hours for hang and finish of board

MANUFACTURING

- Computer modeled – can be extracted from a Revit Model

- Exacting dimensional reliability

- Simple to very complex shapes possible

- Large scale production capability

- Repeatability time after time

DURABILITY

CNC machined Exact Edge shapes are proven to be more durable than mesh corner bead, plastic corner bead, no-coat, and clinch-on.

This video shows a pendulum test simulating an impact from a 250 pound weight.

GET A QUOTE

Exact Edge is distributed exclusively by Gypsum Supply Co. DBA ASI Building Products

Getting a custom quote is easy.

Download our Exact Edge Quote Form, complete and email to Heather Rohdy hrohdy@asibuildingproducts.net

TESTIMONIALS

“Implementation of Exact Edge prefabricated modules on the Park Place Hotel Conference Center greatly contributed to the safety, efficiency and quality of the project. The Bouma installers were able to keep a light footprint, reduce time onsite and deliver a high-end ornamental ceiling with meticulous precision.”

Matt Novak, PE

Leader of Project Management

Triangle Associates, Inc.